British Water is committed to providing our member community with new innovative information on current affairs within the sector. Members can now submit their news directly to our website.

|

Posted By Neilas Svilpa,

30 September 2022

|

Marsh Industries, a leading manufacturer of off-mains drainage products, has launched an innovative, AI-driven sales tool designed to reduce estimating time and pressure on its merchant’s sales forces.

While the merchant supply chain is recovering from both the pandemic and the effects of Brexit, it is also battling with staffing issues, material shortages and rising inflation and transportation costs. As a result of this, one of the single biggest issues that branch managers, regional directors and sales teams are facing is time management.

Steve Boyer, managing director of Marsh, explains “We have seen these time management pressures escalate for merchants over the last three months and we believe it is not currently reasonable to expect merchants to take time out of their day to see our sales teams on routine calls. We can help by using Zoom or telephone appointments, but this will not necessarily help promote current and future sales enquiries. To help improve the situation we have launched our innovative sales support tool, Pinnacle-AV.”

Pinnacle-AV, a first of its kind in the industry, uses artificial intelligence and multimedia to prepare a bespoke quotation module for Marsh sewage treatment plants, pump chambers and oil separators.

The quotation module is comprised of a personalised quote for your customer’s contract requirements, video, design drawings and all relevant process calculations that can then be given to the customer, and regulatory bodies if required, to secure the project.

The Pinnacle-AV quotation module can also be customised using merchant logos, branding elements and contact details.

Mr Boyer continues “We have trialled this solution since March 2022 on a limited scale and the response from merchants was tremendous. Pinnacle-AV enables your sales team to present a detailed technical quotation with confidence to their customers – For example, in a short 3-minute video, Pinnacle-AV can answer all the sales and technical queries your customer or contractor may have.”

“We believe that by working collaboratively with Marsh and using Pinnacle-AV, we can help reduce the time pressure and bring a serious competitive advantage to your merchant sales forces”.

“If you would like a personal presentation, please contact us and I will personally arrange for it to be undertaken.

This post has not been tagged.

Permalink

| Comments (0)

|

|

Posted By Neilas Svilpa,

30 September 2022

|

Marsh Industries, a leader in off-mains drainage solutions, has launched a new series of product knowledge videos for distributors and merchants.

The new series, aptly named ‘Trade Talk’, is intended to provide viewers a better understanding of the wide spectrum of Marsh products in condensed, two- to three-minute video segments.

The videos briefly describe the advantages of Marsh products and can be used as in-house product training and trade counter display for customers.

"Trade Talk is released in tandem with Marsh Pinnacle-AV, an AI-driven sales tool that is aimed to minimise estimation time and burden on merchant's sales personnel," explains Managing Director Steve Boyer.

The main goals of Trade Talk and Pinnacle-AV are to help merchants save time and, more importantly, to help them increase their sales.

The first video, covering the Marsh domestic wastewater treatment range, is already available and can be viewed at www.marshindustries.co.uk/tradetalk

The rest of the series will cover the following product ranges:

• Commercial wastewater treatment: Ultra:Polylok and Marsh:Standard

• Domestic and commercial pump stations

• Oil separators: Hydroil, Marator and grease/silt traps

For merchants and distributors who need copies of the videos for in-house use, please get in touch with the Marsh team on 01933 654582 or sales@marshindustries.co.uk

This post has not been tagged.

Permalink

| Comments (0)

|

|

Posted By Neilas Svilpa,

29 September 2022

|

A simple adjustment to blowers on submerged aerated filter (SAF) technology is bringing significant energy reductions in wastewater treatment, writes Andrew Baird, technical director, WCS Environmental Engineering, meaning cost savings for utilities.

The water sector ranks as the fourth most energy intensive industry in the UK, and utilities in England and Wales, striving to reach net zero carbon by 2030, are now focusing intensely on how to save on power.

Making wastewater treatment more energy efficient is key to companies’ business strategies. For a water company with over 600 treatment works, around 55% of energy usage is in the treatment of wastewater, with its electricity bills coming in at around £25 million a year – that is before the recent increases.

The water sector’s Net Zero 2030 Routemap notes an upward trend in electricity consumption between 2015 and 2019, attributed in part to an increase in water and wastewater treatment driven by rising environmental standards, and more intense rainfall due to climatic changes. Water companies are investing in energy efficiency interventions, with suppliers taking a lead in the development of new technology.

Water recycling specialist WCS Environmental Engineering (WCSEE) has undertaken a five-year study, alongside University of Portsmouth researchers, at Petersfield wastewater treatment works in Hampshire, to enhance process efficiency of its patented Hybrid-SAF technology.

One outcome of the research is the introduction of automated timers to operate the blowers which provide the air for biological treatment processes in WCSEE SAF units. Blowers typically operate 24/7, accounting for more than 90% of the energy used in a SAF unit. They are now timed to pulse air into the process for 15 minute intervals, rather than operate continuously.

Peg timers, similar to those used in central heating systems, are being used as standard with WCSEE’s HiPAF treatment plants, and existing WCSEE SAF technology can be easily retrofitted. This will cut the amount of energy consumed by the blowers by up to 50%, addressing the market need for net zero carbon, reducing energy consumption, and cost efficiencies.

From conversations with utilities, WCSEE understands the need to reduce power consumption of SAF units. The introduction of a timer is a very low cost method of power reduction.

While the concept was simple, finding the optimum times to turn blowers on and off, and determining ideal time-lengths, proved more of a challenge. Part of the research involved exploring the impact of turning the blowers off for longer periods, including overnight.

In general, it was found that the HiPAF saw a reduction in dissolved oxygen after 20-30 minutes. This made it possible to set timers to 15 minutes on and 15 minutes off – so, in operation for half the amount of time while still providing effective aeration for reliable treatment. The 15-minute intervals give the added advantage of not exceeding the hourly on-off cycles required by blower manufacturers to maintain guarantees.

This solution, developed through a long-term collaboration with the University of Portsmouth may be a simple fix, but it is supported by five years of research, and a three-year test period.

These studies have already achieved significant energy and cost savings with the introduction of the patented SAF technology to the biological treatment section, known as the biozone. The patented technology employs a submerged moving-bed, fixed-film reactor which can treat wastewater with greater energy efficiency compared to traditional SAFs, in a tighter site footprint whilst meeting environmental compliance.

Now, with such a huge drive towards energy reduction, this successful timer outcome, combined with the unique patended technology at the heart of our Hybrid SAF range, will contribute to the utilities’ urgent drive to cut their carbon footprints, deliver cost efficiencies and protect the environment.

This post has not been tagged.

Permalink

| Comments (0)

|

|

Posted By Neilas Svilpa,

29 September 2022

|

• Custom onsite treatment required for high-end dwellings

• Rural location required careful design

• Nitrate removal capability considered in nutrient neutrality calculations

The developers of high-end properties built on a historic Hampshire estate have selected WCS Environmental Engineering (WCSEE) technology to treat wastewater flows to strict environmental standards.

The Home Farm development of 23 properties is situated in Embley Park, Romsey, a picturesque 18th century estate. The wider park houses Florence Nightingale’s former family home, now an independent school, and is located at the edge of the New Forest.

Because of its rural location, the new development is unable to connect to the public sewer network and therefore onsite wastewater treatment is required. Environment Agency discharge permit requirements are particularly stringent, due to the park’s sensitive receiving waters.

The high environmental standards required include 10mg/l biological oxygen demand (BOD), 15mg/l suspended solids, and 5mg/l ammonia. To ensure compliance is met, WCSEE has designed a custom onsite solution, comprising a below-ground HiPAF® (high performance aerated filter) treatment plant and 3.1 x 2.6m sand filter, also below ground.

The sand filter will remove any excess suspended solids from the treated wastewater before it is discharged, providing a level of tertiary treatment to bring discharge consent standards above what is normally expected from a biological process.

Additionally, the planning authority – Test Valley Borough Council – has a nutrient neutral policy in place for new residential developments. Nutrient neutrality is a means of ensuring new residential developments do not increase the nutrient burden of nearby protected waters.

WCSEE liaised with developer Capital Homes’ nutrient neutrality adviser throughout the design of the plant, to ensure the technology’s nitrate removal capability was considered as part of the neutrality calculations, submitted as part of the planning application.

WCSEE technical manager Dominic Hamblin: “We are proud that our technology has been selected by Capital Homes for this historic and environmentally sensitive site.

“Working closely with Capital Homes and their engineering consultants BP Civils, we have designed a high-end solution that is fully compliant and offers the highest levels of environmental protection, even in this sensitive spot.

“Due to the site’s rural location, our engineers have been conservative in the plant’s design, including reducing the tank’s original size by one metre, taking into account narrow access roads to avoid future issues when it comes to installation and maintenance.

“The nutrient neutrality approach was another area that made this project particularly interesting, and we were pleased to offer our technical expertise to help bring the desired outcome.”

Capital Homes managing director Mike Paddock said: “We have been pleased to work with WCSEE to bring the highest quality wastewater treatment to Home Farm. We have collaborated closely with their technical experts throughout the design process and we look forward to the installation and commissioning stage, expected this summer.”

WCSEE’s HiPAF technology is suitable for properties from 60 up to 2,000 population equivalent (PE) where mains drainage is unavailable. Modular in design and built off site, the units are simple to install, operate and maintain.

This post has not been tagged.

Permalink

| Comments (0)

|

|

Posted By Neilas Svilpa,

29 September 2022

|

Hired technology from water recycling specialist WCS Environmental Engineering (WCSEE) has been selected by a Somerset nursing home to provide onsite wastewater treatment that ensures high environmental standards.

Chelston Park is a 31-room nursing and residential home, in Wellington, six miles from Taunton, UK. In a rural location and not connected to the public sewer, the property is served by an onsite wastewater treatment plant and reed bed.

When part of the system reached the end of its operational life, it was taken out of service and the business needed a temporary solution to ensure high standards of treatment were maintained while a permanent fix was planned out. With tankering proving costly, the business and its specialist consultant Cress Water, opted to hire a submerged aerated filter (SAF) unit and blower on a temporary basis from WCSEE.

Connected between the existing inlet and final settlement tanks, the unit will provide the biological treatment process with technology that meets high standards for biochemical oxygen demand (BOD), ammonia, and soluble chemical oxygen demand (COD).

WCSEE technical manager Dominic Hamblin said: “We are pleased to supply equipment for this temporary but important project at Chelston Park, to ensure its onsite wastewater treatment plant can maintain high environmental standards while part of the existing system is out of action. Hiring mobile SAF units enables sites undergoing reactive work, or planned refurbishment, to remain fully operational and within environmental consent.

“While wastewater from a nursing home is classed as domestic, you would expect there to be more washing up and laundry flows which need to be considered as part of the treatment process. Our temporary units are flexible and can easily manage this kind of effluent, connecting quickly and easily to existing units. The modular units operate on a “plug and play” basis and can be configured in any combination.

“With a large property such as this, tankering costs can quickly add up. Hiring WCS SAF units, whether short or long-term, is far more cost-effective and gives facility managers time to scope out a permanent solution.”

Chelston Park estates and business development manager Edward Allistone said: “Being in a beautiful rural location, we care for our surrounding environment and do not want to impact it. Hiring a wastewater treatment unit from WCSEE, while part of our system is out of service, has put our mind at ease – we know we can continue to treat effluent onsite in an environmentally friendly way, without the need for tankers.”

WCS Environmental Engineering is a part of the WCS Group, which has the in-house skills and expertise in place to deliver full turnkey solutions from influent to effluent, with the capability to close the loop with water reuse.

This post has not been tagged.

Permalink

| Comments (0)

|

|

Posted By Neilas Svilpa,

29 September 2022

|

The UK’s largest dog welfare charity has selected an enhanced effluent treatment technology to meet stringent regulations at its rehoming centre in Northern Ireland.

A site expansion and tightening environmental consents has led Dogs Trust to upgrade the onsite wastewater treatment plant at its centre in Ballymena, Country Antrim. Animal waste is categorised as controlled waste, with treatment governed by more stringent regulations than domestic waste.

The system is being delivered by specialist WPL, a WCS Environmental Engineering (WCSEE) company.

Working alongside the charity’s project managers Soma Services, WCSEE designed and manufactured a modular HiPAF® (high performance aerated filter) treatment plant, with a robust aerobic digestion system (RADS), to replace the existing plant. In addition, a new sand filter will provide a level of tertiary treatment.

The solution has been designed to meet a Northern Ireland Environment Agency (NIEA) discharge consent of 10:15:10mg/l for ammonia and suspended solids and 10mg/L biological oxygen demand (BOD).

The HiPAF is most appropriate for commercial and domestic applications where the site is not connected to mains drainage and is well suited to complex requirements, such as the treatment of animal waste. RADS is a cost efficient, low maintenance sludge treatment system which runs alongside the biological plant.

The introduction of the RADS process will not only ensure optimum performance but will provide significant savings in tankering costs.

The HiPAF and RADS have been successfully installed at many animal centres such as kennels, catteries and stables. On completion of the latest installation at Ballymena, a total of nine WCSEE systems will be in operation at Dogs Trust sites around the UK.

Technical manager Dominic Hamblin said: “We are proud to be supplying our ninth specialist treatment systems to Dogs Trust’s Ballymena site, to ensure compliance with stringent environmental standards.

“The waste generated by this type of establishment is very difficult to treat and for those locations not connected to mains drainage, reliable onsite treatment systems are critical if environmental permit conditions are to be maintained. It is a testament to the combined process expertise of WCSEE and project partner Soma Services that we have again been selected by Dogs Trust to deliver a robust solution.”

Pete Croft, Dogs Trust building surveyor, said: “It is important to Dog Trust that all our sites are operated as efficiently as possible and in compliance with the relevant environmental standards. This is particularly challenging where centres are expanding.

“From our previous wastewater treatment upgrades, we know the introduction of the RADS system will make a significant difference to the amount of desludging required as part of the treatment process and will reduce associated costs as a result. We are very happy with the work that Soma Services and WCSEE have done for us over the years and are pleased to be working with them once again on this important project in Ballymena.”

Rob Hunt, Soma Services managing director, said: “Soma Services are proud to have worked with Dogs Trust since 2006 and, in close association with equipment suppliers WCSEE, have provided innovative cost-effective turnkey solutions to their challenging wastewater treatment needs. Over 20 years’ experience of treatment plant installation and maintenance enables our clients’ requirements to be met in a wide range of situations.”

The technology will be installed by Soma Services and the project is expected to be delivered by summer 2022.

WCS Environmental Engineering is a part of the WCS Group, which has the in-house skills and expertise in place to deliver full turnkey solutions from influent to effluent, with the capability to close the loop with water reuse.

A previous WCSEE install at a Dogs Trust centre in Ilfracombe

This post has not been tagged.

Permalink

| Comments (0)

|

|

Posted By Neilas Svilpa,

29 September 2022

|

New energy saving measures developed by WCS Environmental Engineering (WCSEE) could reduce power consumption of its package wastewater treatment plants by as much as half.

The water recycling specialist has introduced automated timers to operate blowers in the biological treatment section of its patended HiPAF (high performance aerated filter) package treatment plants.

Blowers account for more than 95% of the energy used in a typical wastewater treatment plant. They usually operate 24/7 to blow air into biological treatment processes, providing oxygen to the bacteria that decompose organic substances in the wastewater, ensuring high standards of treatment are maintained.

Blowers in WCSEE’s HiPAF range are now timed to pulse air into the process, rather than operate continuously. The timers will be built in as standard to the HiPAF range of treatment plants, cutting the amount of energy used to treat effluent by up to 50%. This can contribute to companies’ net zero carbon emission goals, as well as bringing welcome reductions in energy costs.

WCSEE technical director Andrew Baird said: “Net zero carbon strategies are front of mind for businesses, with energy efficiencies critical to meeting climate goals. At the same time, businesses are facing huge rises in energy bills and cutting power consumption is now a priority for many to try and control costs.

“Building in timers to blowers has proven to be a simple and low-cost option to reduce power consumption by up to 50%, addressing the market need for both net zero and cost efficiencies.”

The timer concept was tested over three years by University of Portsmouth researchers at its facility at Petersfield wastewater treatment works, Hampshire, to ensure compliance was always maintained.

Baird said: “While the concept was simple, finding the right times to turn blowers on and off and for what periods proved more of a challenge. In general, we found the HiPAF only saw a reduction in dissolved oxygen after 20-30 minutes, allowing us to set timers to 15 minutes on and 15 minutes off.

“These intermittent pulses provide effective aeration for reliable treatment, while consuming significantly less energy. The 15 minutes intervals give the added advantage of not exceeding the on off cycles per hour required by the blower manufacturers, to maintain the blower guarantee.”

Substantive research

The addition of timers has come as a result of part of WCSEE’s substantive research and development to enhance process efficiency of its HiPAF technology.

These studies have already achieved significant energy and cost savings with the introduction of the patented Hybrid-SAF (submerged aerated filters) technology to the biological treatment section, known as the biozone. The patented technology employs a submerged moving-bed, fixed-film reactor which can treat wastewater with greater energy efficiency compared to traditional submerged SAFs, in a tighter site footprint whilst meeting environmental compliance.

Baird said: “SAF treatment is traditionally viewed as a high cost process due to the energy requirement in delivering high volumes of air, and is generally not considered for larger schemes.

“At the heart of our Hybrid SAF technology are unique flow characteristics that have been patented. These ensure an even and continuous flow of nutrients up

through the submerged, moving bed.

“The slowly circulating media gradually descends due to its increasing specific gravity from hosting biomass growth. Calculating the impact of gravity on the process results in a significant reduction in power consumption, improving overall efficiency and enabling a reduction in site footprint and a deployment of a more compact unit.”

Developments in hydraulic control and retention times have also enabled the patented process technology to consistently achieve final effluent ammonia concentrations of less than 1mg/l on a 95%ile basis.

WCSEE HiPAF plant and kiosk.

This post has not been tagged.

Permalink

| Comments (0)

|

|

Posted By Neilas Svilpa,

29 September 2022

|

Kingspan Klargester has become the first water management solutions manufacturer in the world to get ISO 37301 accreditation. This new standard has been designed to offer organisations clear guidance and direction around effective compliance management.

The introduction of the accreditation has been widely welcomed, particularly as it comes at a time when non-compliance with legally binding standards by a business is likely to be catastrophic.

The accreditation specifies the requirements for establishing, developing, implementing, evaluating, maintaining, and improving an effective compliance management system across a business. It focuses on the development and application of robust compliance policies, all of which is expected to reduce rule violations – as well as the financial penalties and reputational damage that typically follow.

Kingspan’s decision to roll out this accreditation across its global business is in-line with the company’s values and its determination both to deliver quality products and to set challenging performance standards.

The accreditation also underlines the organisation’s belief in close market regulation, particularly where this is employed to protect customer interests.

It also supports the company’s commitment to Planet Passionate, its 10-year, group-wide, global sustainability strategy, which aims to impact on three big global issues: climate change, circularity, and protection of the natural world.

The roll-out across the Kingspan Klargester business began with its British and Irish facilities and will soon extend across all the divisional sites in Europe.

“Our decision to get accreditation is based on the belief that we should always strive for better in areas such as governance, integrity, accountability, transparency and sustainability, all of which lie at the heart of this standard,” says Water Business Unit Director David Anderson.

“Compliance management is deeply embedded into our working practices, and we firmly believe this should be the case right across our industry.

“The ISO 37301 is the gold-standard for compliance management, and we’d like to encourage everyone working in the water sector to consider applying it to their business.”

This post has not been tagged.

Permalink

| Comments (0)

|

|

Posted By Neilas Svilpa,

09 September 2022

|

An industrial filter maker is set to highlight how its solutions can help the water sector manage the challenges of climate change, ongoing pricing reviews and rising customer demand.

Experts from Amazon Filters will focus on water companies’ need for ‘resilience and strategic planning’ when they exhibit at the seventh annual Drinking Water Quality Conference.

A key theme of this year’s event, taking place at Birmingham Hilton Metropole on 5 October 2022, is how companies can maintain the highest water quality while planning for future risks.

Amazon Filters’ Head of UK Sales Lisa Astbury and Sales Engineer Gareth Davies will both be on the exhibition stand.

Lisa said: “The water sector continues to be under intense scrutiny after a summer of drought and measures such as hose pipe bans that have affected millions of consumers.

“We have made and supplied critical filtration solutions to the water industry in the UK and Europe for 37 years, helping users to safeguard precious water resources right the way through from source to tap.

“Water quality management is all about resilience and strategic planning and what we do is use our ‘quick and able’ manufacturing capability to help companies guarantee a consistent level of quality for safety and regulatory compliance.

“Our input supports essential activities such as drought management, turbidity control, chlorine reduction and the removal of iron, manganese, cryptosporidium and other contaminants and chemicals.”

Among the products Amazon Filters will be exhibiting is SupaSpun II, an absolute-rated depth filter that is on the approved list for use in the public water supply under DWI Regulation 31.

The conference will feature presentations from Marcus Rink, Chief Inspector of the Drinking Water Inspectorate, and senior figures at companies including Scottish Water, Anglian Water, Southern Water, Yorkshire Water and Thames Water, many of which are already Amazon Filters customers.

Among the event partners are membership organisation British Water, research body UK Water Industry Research and the networking and knowledge exchange group SWIG (Sensors for Water Interest Group).

For further details of the conference, visit https://events.utilityweek.co.uk/event/7fd00545-1e4e-4933-9989-cc5492a7e3fd/summary

For more information from Amazon Filters, visit www.amazonfilters.com.

BUILDING RESILIENCE. Filtration equipment made by Amazon Filters in position to support bore water turbidity control during wintry conditions. The manufacturer provides containerised systems and skid rentals to help municipal water companies mitigate shortages and build resilience for drought, flooding and other potential disruptions to supply. Experts from Amazon Filters will be at the Drinking Water Quality Conference to highlight the solutions and products available.

This post has not been tagged.

Permalink

| Comments (0)

|

|

Posted By Neilas Svilpa,

11 August 2022

|

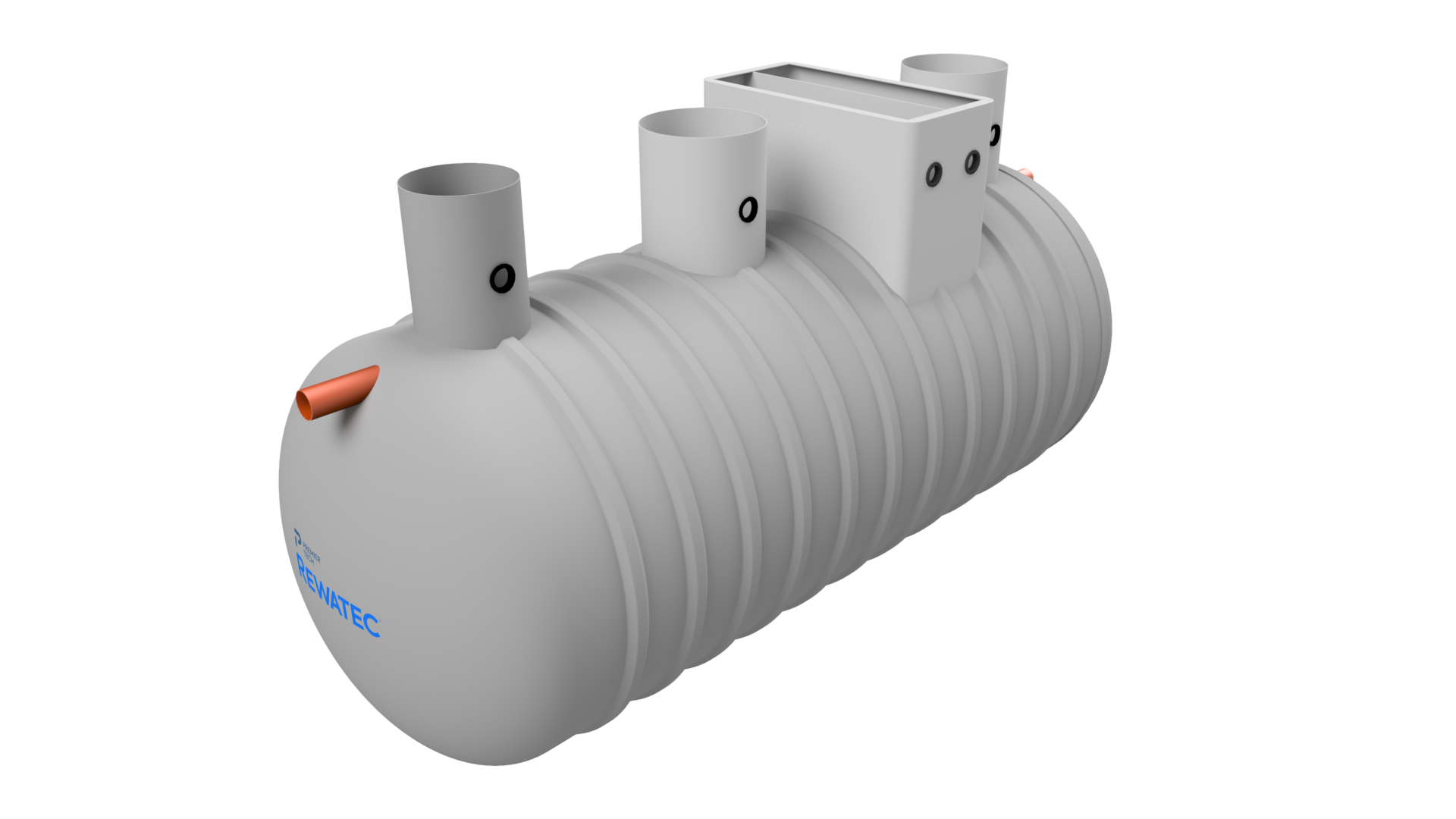

Premier Tech enhance their range of Rewatec Submerged Aerated Filter (SAF) sewage treatment plants

Premier Tech Water and Environment has enhanced their range of Rewatec SAF sewage treatment plants to combine energy efficiency with an exceptionally high wastewater treatment performance.

As part of the redesign, the Rewatec SAF now features an internal baffle in the primary chamber to assist with the removal of solids and organics, and to prevent potential blockages downstream. A new pipe arrangement to optimise the level of oxygen induced into the biozone chamber, also improves the operational efficiency of wastewater treatment. Other unique attributes such a simpler manifold design and a new manifold extension kit increase the overall reliability of the plant, whilst also making it easier to install, commission, service and maintain.

All Rewatec SAF plants are supplied with a robust kiosk to house the electronic and mechanical componentry required to operate the system. Innovative features such as temperature and pressure alarms and air filter monitoring are included as standard, with options such as acoustic lining and GSM and/or BMS communication for remote plant monitoring, available upon request.

A variable speed three phase blower to increase efficiency, reduce energy usage, reduce costs and lower the overall carbon footprint, can be installed within the kiosk on all plants above 100 PE. An optional probe can also be supplied to regulate the air supply in the biozone chamber, again maximising energy efficiency whilst reducing cost for the end user.

Dr Evangelos Petropoulos – Senior Technical Engineer commented:

“As an environmental company we have the moral obligation to protect our water resources and pass them to our children in a state better than that we had received from our ancestors. To ensure a more sustainable future, we continuously develop more efficient, more reliable, and easier to operate wastewater treatment systems. To further enhance this commitment and to provide the best-in-class product, we are proud to release our new generation of SAF wastewater treatment plants.

This is only possible due to the strong relationships we have with our customer partners, many of whom were heavily involved in every aspect of development. The feedback they provided in terms of technical requirements, operational efficiency, installation and design were all carefully considered. This has resulted in a highly efficient and highly reliable system that has surpassed their expectations”.

Uniquely engineered from robust GRP, the Rewatec SAF can cater for commercial businesses and residential communities with a population of up to 600 people. Bespoke designs to meet specific application parameters, seasonal usage fluctuations and larger population requirements, can also be manufactured in consultation with Premier Tech’s expert in house engineering team, to meet the exact needs of end-users, engineers, architects, specifiers and consultants.

Designed, manufactured and tested in accordance with EN12566-3 for plants below 50PE, EN12255 for plants above 50PE and the British Water Code of Practice for Flows and Loads, the Rewatec SAF is capable of meeting strict effluent standards that exceed UK environmental discharge requirements, for a range of on-site applications that don’t have access to the main sewage network. To find out more visit: https://www.premiertechaqua.com/en-gb/wastewater-treatment/sewage-treatment-plant-saf

This post has not been tagged.

Permalink

| Comments (0)

|

|